Why Does Signal Interference Occur in LVDS Cables During Use?

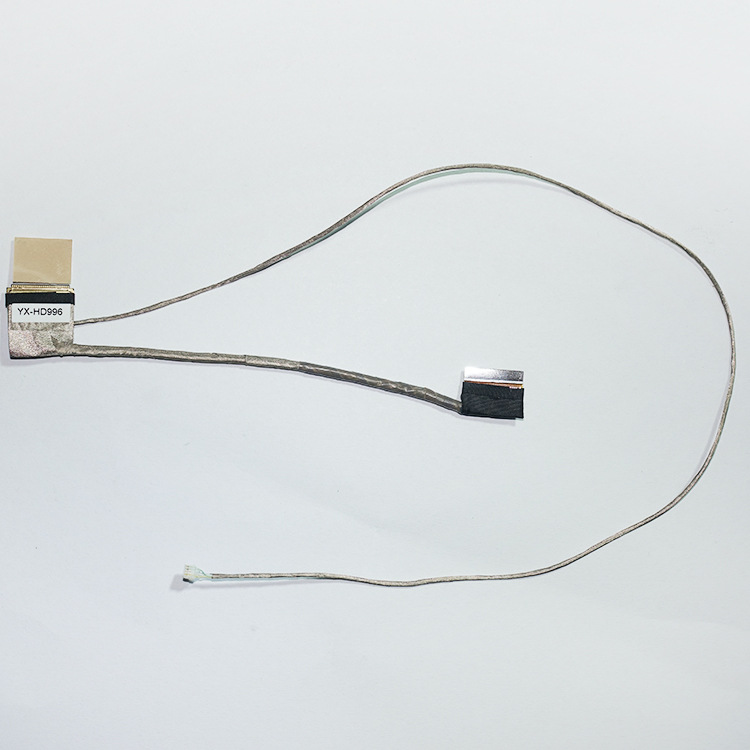

LVDS (Low-Voltage Differential Signaling) Cables are designed to minimize signal interference through their differential pair structure and low-voltage operation—yet interference still occurs in real-world use, leading to issues like screen flicker, data dropouts, or distorted images. This interference undermines the core advantage of LVDS technology and can disrupt critical systems, from consumer electronics to industrial automation. To resolve the problem, it’s essential to understand its root causes, which stem from flaws in cable design, improper installation, harsh environmental factors, or compatibility mismatches. Below is a detailed breakdown of why signal interference affects LVDS Cable and how each factor contributes to performance degradation.

1. Deficiencies in Cable Design: Compromised Noise Resistance

The anti-interference capability of an LVDS Cable starts with its design. Even small deviations from industry standards can create vulnerabilities to external noise. Three common design flaws are particularly problematic:

a. Inadequate or Damaged Shielding

Shielding is the first line of defense against external electromagnetic interference (EMI). LVDS Cables rely on foil, braided, or dual (foil + braid) shielding to block EMI from sources like power lines, motors, or nearby electronics. However:

-

Low-quality shielding: Budget cables may use thin, incomplete foil shielding or loosely woven braids (with <80% coverage). Gaps in the shield allow EMI to penetrate the cable and disrupt the differential signal. For example, a braided shield with 60% coverage will let 40% of external EMI reach the conductors.

-

Shield damage during manufacturing: Poorly assembled cables may have torn foil or disconnected braids. A tiny tear in the foil—even 1mm wide—can act as an “antenna,” picking up high-frequency EMI (e.g., from Wi-Fi routers or industrial inverters).

In industrial settings, where EMI levels are high, a cable with inadequate shielding will experience frequent signal glitches. For instance, an LVDS Cable connecting a machine vision camera to a controller might pick up EMI from a nearby motor, causing the camera to send distorted images.

b. Imperfect Differential Pair Construction

The differential pair (two twisted conductors) is the heart of LVDS’s noise-canceling ability. For this to work, the pair must be balanced—i.e., the two wires must have identical length, impedance, and spacing. Design flaws here break this balance:

-

Uneven twist pitch: The twist pitch (number of twists per inch) controls how evenly EMI affects the two wires. If the pitch varies (e.g., some sections twist once per inch, others twice), EMI will impact one wire more than the other. This breaks the “common-mode rejection” (CMR) effect, allowing noise to remain in the signal.

-

Length mismatch: If one wire in the pair is even 1mm longer than the other, signal skew (time delay between the two signals) increases. Skew above 50 picoseconds (ps) prevents the receiver from fully canceling noise, leading to data errors. For example, a 2mm length mismatch in a 10-meter cable can cause 30ps skew—enough to disrupt 1Gbps data transmission.

c. Low-Quality Conductors or Insulation

Conductors and insulation directly impact signal integrity:

-

Copper-clad aluminum (CCA) conductors: Many cheap LVDS Cables use CCA instead of pure or tinned copper. CCA has higher electrical resistance, causing signal attenuation (weakening) over distance. Attenuated signals are more vulnerable to EMI, as the noise becomes a larger portion of the overall signal.

-

Poor insulation materials: Low-grade plastics (e.g., recycled PVC) have inconsistent dielectric properties. This causes impedance fluctuations along the cable—impedance mismatch reflects signals back to the transmitter, creating “echoes” that interfere with the original signal. In extreme cases, the insulation may crack over time, exposing the conductors to direct EMI.

2. Improper Installation: Creating Unintended Interference Paths

Even a well-designed LVDS Cable can suffer interference if installed incorrectly. Installation mistakes introduce physical or electrical paths for noise to enter the system:

a. Proximity to High-EMI Sources

LVDS Cables should never be routed near strong EMI sources, but this rule is often ignored in tight spaces (e.g., inside a laptop or industrial control panel). Common high-EMI sources include:

-

Power cables (AC mains or DC power supplies for motors).

-

Electronic components like inverters, transformers, or wireless modules (Wi-Fi/Bluetooth).

When an LVDS Cable runs parallel to a power cable, the power cable’s magnetic field induces a noise current in the LVDS conductors. For example, routing an LVDS Cable next to a 24V DC motor power cable can cause 50Hz hum interference—visible as horizontal lines on a display connected to the cable.

b. Excessive Bending or Stretching

LVDS Cables are flexible, but overbending or stretching damages their internal structure:

-

Bending beyond the minimum bend radius: Most LVDS Cables have a minimum bend radius (e.g., 10x the cable diameter). Bending tighter than this (e.g., folding a 5mm cable into a 20mm radius) can twist the differential pair unevenly, increasing skew. It may also crack the shielding or insulation, exposing the conductors.

-

Stretching during installation: Pulling the cable too hard (e.g., to fit into a tight space) stretches the conductors, changing their length and impedance. A stretched cable may have a 15% impedance mismatch, leading to signal reflection and interference.

c. Loose or Mismatched Connectors

Connectors are a common weak point for interference:

-

Loose connections: A connector not fully seated in the port creates a gap between the cable’s pins and the device’s socket. This gap increases contact resistance, causing signal loss and introducing noise. For example, a loose JAE MX19 connector in a laptop can cause intermittent screen flicker as the connection fluctuates.

-

Mismatched connector types: Using a connector not designed for LVDS (e.g., a generic USB connector) disrupts the differential pair’s impedance. Mismatched connectors also lack the shielding of LVDS-specific connectors, allowing EMI to enter through the port.

3. Harsh Environmental Conditions: Accelerating Degradation

Environmental factors can degrade

LVDS Cables performance over time, making them more susceptible to interference:

a. Extreme Temperatures

LVDS Cables are rated for specific temperature ranges (e.g., -20°C to 70°C for consumer use, -40°C to 85°C for industrial use). Operating outside these ranges damages key components:

-

High temperatures (>85°C): Soften the insulation, causing the differential pair to shift and increasing skew. It can also melt the shielding adhesive, separating the shield from the conductors.

-

Low temperatures (<-40°C): Make the insulation brittle, leading to cracks that expose the conductors to EMI. For example, an LVDS Cable in a car’s dashboard (exposed to -30°C in winter) may develop insulation cracks, picking up EMI from the car’s engine control unit.

b. Moisture or Chemical Exposure

Moisture and chemicals corrode the cable’s shielding and conductors:

-

Moisture: Water or humidity seeps through small gaps in the jacket, oxidizing copper conductors and shielding. Oxidation increases resistance, weakening the signal and making it more vulnerable to noise. In outdoor applications (e.g., digital signage), unweatherproofed LVDS Cables often fail due to moisture-induced interference.

-

Chemicals: Industrial environments with oils, solvents, or corrosive gases (e.g., factories, labs) can dissolve the cable’s jacket or insulation. This exposes the internal components to EMI and physical damage.

4. Compatibility Issues: Mismatched System Components

Interference can also arise from incompatibility between the LVDS Cable and other system components:

-

Transmitter/receiver mismatch: The LVDS Cable must match the impedance of the transmitter (e.g., a graphics card) and receiver (e.g., a display panel). If the cable’s impedance (e.g., 90 ohms) doesn’t match the device’s impedance (e.g., 100 ohms), signal reflection occurs, creating interference.

-

Voltage mismatch: Some older LVDS devices use 5V signaling, while modern ones use 3.3V. Using a cable designed for 5V with a 3.3V device reduces signal strength, making it easier for EMI to overwhelm the signal.

Signal interference in LVDS Cables is rarely caused by a single factor—it’s often a combination of design flaws, poor installation, environmental damage, or compatibility issues. By understanding these root causes, users can take proactive steps to prevent interference: choosing high-quality, shielded cables with balanced differential pairs, routing cables away from EMI sources, following installation guidelines (e.g., minimum bend radius), and ensuring compatibility with system components. Addressing these issues ensures that LVDS Cables deliver the reliable, low-noise performance they’re designed for—whether in a laptop, factory, or car.