How to Select an LVDS Cable?

Choosing the right LVDS (Low-Voltage Differential Signaling) Cable is critical to ensuring reliable, high-performance data transmission—whether for a laptop display, industrial camera, or automotive infotainment system. A mismatched or low-quality LVDS Cable can lead to signal degradation, screen flicker, system crashes, or even permanent device damage. To avoid these issues, buyers need to follow a structured approach that aligns the cable’s specifications with their specific application needs. Below is a step-by-step guide to selecting an LVDS Cable, covering key considerations from performance parameters to practical testing.

1. Start by Defining Your Application Requirements

The first and most foundational step is to clarify what the LVDS Cable will be used for—as different applications demand vastly different cable specifications. Ask yourself these questions to narrow down your needs:

-

What device are you connecting?

LVDS Cables vary by end-use: a cable for a 4K LCD TV will have different bandwidth needs than one for an industrial machine vision camera. For example, consumer electronics (laptops, smartphones) prioritize compactness and low power, while industrial applications require ruggedness and noise resistance.

-

What data rate and bandwidth do you need?

Calculate the minimum bandwidth required for your device. A 1080p display needs ~3 Gbps, while a 4K display requires ~18 Gbps. Ensure the LVDS Cable supports this bandwidth—most cables specify a “maximum data rate” (e.g., 2 Gbps per pair) or “aggregate bandwidth” (for multi-pair cables). For high-bandwidth needs, opt for multi-pair cables (4 or 8 pairs) to avoid bottlenecks.

-

What is the transmission distance?

LVDS Cables typically support 1–15 meters for high-speed data (1+ Gbps), but longer distances (20+ meters) may require “extended-range” cables or repeaters. Avoid using a standard short-range cable for long distances, as this will cause signal attenuation (loss) and errors.

-

What is the operating environment?

Consider factors like temperature (e.g., -40°C to 85°C for automotive use), moisture (waterproofing for outdoor devices), and EMI (electromagnetic interference) levels. Industrial or automotive environments need shielded cables with rugged jackets, while home electronics can use unshielded or lightly shielded options.

2. Prioritize Key Electrical Performance Parameters

Once you’ve defined your application needs, evaluate the LVDS Cable’s electrical specifications—these directly impact signal quality and reliability. Focus on these critical parameters:

a. Impedance Matching

LVDS Cables require precise impedance (resistance to AC signals) to prevent signal reflection, which causes data errors. The industry standard for LVDS is 100 ohms ±10% (measured between the two wires of the differential pair). A cable with mismatched impedance (e.g., 80 or 120 ohms) will reflect signals back to the transmitter, leading to distorted data (e.g., screen artifacts in displays). Always check the manufacturer’s datasheet for impedance values.

b. Signal Skew

Signal skew refers to the time delay between the positive (+) and negative (-) signals in the differential pair. Even a small skew (e.g., >50 picoseconds) can disrupt the receiver’s ability to subtract the two signals, resulting in noise or data loss. Look for cables with skew <30 ps for high-speed applications (1 Gbps+). Skew is minimized by tightly controlled twisted pair pitches and equal-length conductors.

c. Attenuation

Attenuation measures how much the signal weakens over distance. For LVDS Cables, attenuation should be <0.5 dB/meter at 1 GHz (a common test frequency). Lower attenuation means the signal remains strong over longer distances. Avoid cables with high attenuation (e.g., >1 dB/meter) for applications requiring transmission beyond 5 meters.

d. EMI Shielding Effectiveness

If your application is in a noisy environment (e.g., factories, cars), choose a cable with robust shielding. Look for:

-

Foil shielding: A thin aluminum layer that blocks low-frequency EMI.

-

Braided shielding: A woven copper mesh that provides better high-frequency EMI protection (ideal for industrial use).

-

Dual shielding (foil + braid): The highest level of protection, recommended for automotive ADAS or medical imaging devices.

The datasheet may specify shielding effectiveness (e.g., >60 dB at 100 MHz)—higher values mean better EMI resistance.

3. Evaluate Physical and Mechanical Quality

A durable LVDS Cable will withstand daily use and environmental stress. Inspect these physical attributes before purchasing:

a. Conductor Material and Gauge

-

Material: Opt for tinned copper conductors over bare copper—tinning prevents oxidation (which degrades conductivity) and improves solderability. Avoid cables with copper-clad aluminum (CCA) conductors, as they have higher resistance and lower durability.

-

Gauge: Conductor gauge (thickness) affects current capacity and flexibility. For most applications, 28–32 AWG (American Wire Gauge) is ideal: 28 AWG offers better durability for long runs, while 32 AWG is more flexible for compact devices (e.g., smartphones). Thicker gauges (e.g., 26 AWG) are unnecessary for LVDS (low current) and add bulk.

b. Insulation and Jacket Materials

-

Insulation: The conductor insulation (between the differential pair) should be made of polyethylene (PE) or ethylene tetrafluoroethylene (ETFE)—these materials have low dielectric loss (critical for signal integrity) and resistance to heat.

-

Jacket: The outer jacket protects the cable from physical damage. Choose:

-

PVC: Cost-effective for indoor use (e.g., home electronics) but not suitable for high temperatures (>60°C).

-

Polyurethane (PU): Flexible and oil-resistant, ideal for automotive or industrial applications.

-

PTFE: Heat-resistant (up to 260°C) for extreme environments (e.g., medical equipment sterilization).

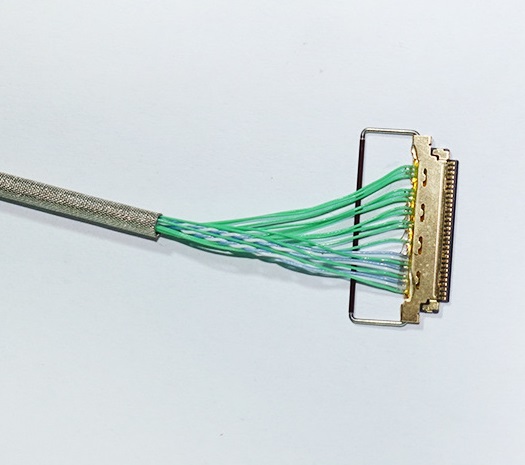

c. Connector Compatibility and Quality

LVDS Cables use specialized connectors—ensure the connector matches your device’s port. Common types include:

-

JAE MX19: Used in laptops and LCD displays.

-

Hirose DF19: Popular for industrial cameras and IoT devices.

-

Samtec FTSH: High-speed connectors for data rates up to 10 Gbps.

Check for gold-plated connector pins—gold resists corrosion and ensures a low-resistance connection. Loose or poorly fitted connectors will cause intermittent signal loss, so test the connector’s fit (it should snap securely into the port).

4. Verify Compliance with Standards and Certifications

Reputable LVDS Cables meet industry standards to ensure consistency and safety. Look for these certifications:

-

CE (Conformité Européenne): Indicates compliance with EU electromagnetic compatibility (EMC) and safety standards.

-

UL (Underwriters Laboratories): Certifies fire safety (e.g., UL 94 V-0 for flame retardancy) and electrical performance.

-

RoHS (Restriction of Hazardous Substances): Ensures the cable is free of lead, mercury, and other toxic materials—critical for consumer electronics sold globally.

For automotive applications, check for ISO 10605 (EMC testing for automotive cables) or IATF 16949 (quality management for automotive suppliers). Medical applications may require IEC 60601 (safety standards for medical devices).

5. Test the Cable Before Full Deployment

Even with perfect specifications, real-world performance can vary. Conduct these simple tests to validate the cable:

-

Visual inspection: Check for frayed jackets, loose connectors, or uneven twisted pairs.

-

Signal quality test: Use an oscilloscope to measure signal integrity (e.g., impedance, skew, attenuation) at your device’s operating frequency.

-

Functional test: Connect the cable to your device and run a stress test (e.g., play 4K video for 24 hours, transmit continuous sensor data) to check for crashes, artifacts, or dropouts.

Selecting an LVDS Cable requires balancing application needs with technical specifications. By defining your requirements (bandwidth, distance, environment), prioritizing electrical parameters (impedance, skew, attenuation), evaluating physical quality (conductors, shielding, connectors), verifying certifications, and conducting tests, you can choose a cable that delivers reliable performance and durability. Avoid generic “one-size-fits-all” cables—invest in a product tailored to your device, and you’ll minimize downtime, reduce maintenance costs, and ensure optimal operation for years to come.