What is a LVDS Cable?

In the realm of high-speed data transmission, Low-Voltage Differential Signaling (LVDS) has emerged as a critical technology, and the LVDS Cable—the physical medium that carries LVDS signals—plays an indispensable role in connecting devices across industries. From consumer electronics like laptops and televisions to industrial automation systems and medical imaging equipment, LVDS Cables enable reliable, high-bandwidth data transfer while addressing key challenges such as signal interference, power consumption, and space constraints. To fully grasp their importance, let’s break down their definition, working principles, core components, key characteristics, and real-world applications.

1. Defining LVDS Cables: Beyond Basic “Wires”

At its core, an LVDS Cable is a specialized transmission cable designed to carry Low-Voltage Differential Signaling (LVDS) signals—an electrical signaling standard developed by National Semiconductor (now part of Texas Instruments) in the 1990s. Unlike traditional single-ended cables (which use one wire to transmit a signal and a ground wire for reference), LVDS Cables rely on a “differential pair” of wires: two closely spaced, twisted conductors that transmit identical signals with opposite polarities (one positive, one negative).

The term “low-voltage” is critical here: LVDS operates at extremely low voltage levels (typically 350 mV peak-to-peak), far lower than older signaling standards like TTL (Transistor-Transistor Logic, ~5V) or RS-232 (~±15V). This low-voltage design, combined with the differential signaling method, is what sets LVDS Cables apart from generic data cables—and what makes them ideal for high-speed, noise-sensitive applications.

2. How LVDS Cables Work: The Science of Differential Signaling

To understand LVDS Cables, it’s first necessary to unpack the differential signaling principle they rely on. Here’s a step-by-step breakdown of how they transmit data:

Step 1: Signal Generation at the Transmitter

At the source device (e.g., a laptop’s graphics card or an industrial camera’s sensor), an LVDS transmitter converts parallel data (multiple bits sent simultaneously) into a serial LVDS signal. It then splits this signal into two identical streams: one “positive” (+) and one “negative” (-). These two streams are sent down the two wires of the differential pair in the LVDS Cable.

Step 2: Signal Transmission Through the Cable

As the signals travel through the cable, they encounter external electromagnetic interference (EMI)—a common problem in environments with motors, power lines, or other electronic devices. Crucially, because the two wires in the differential pair are closely twisted and carry opposite-polarity signals, EMI affects both wires equally. For example, if a stray electromagnetic field induces a +100 mV noise signal on the positive wire, it will also induce a +100 mV noise signal on the negative wire.

Step 3: Signal Reconstruction at the Receiver

At the destination device (e.g., a laptop screen or a control system’s processor), an LVDS receiver compares the two signals from the differential pair. It calculates the “difference” between the positive and negative signals: (Positive Signal) - (Negative Signal). Since EMI affected both signals equally, the noise cancels out in this subtraction (e.g., (Signal + 100 mV) - (Signal’ - 100 mV) = (Signal - Signal’) + 200 mV—but because the original signals are opposites, Signal = -Signal’, so the noise term (200 mV) is eliminated). The receiver then converts the clean differential signal back into parallel data for the device to use.

This noise-canceling ability is the “superpower” of LVDS Cables: it allows them to transmit data over longer distances (up to 10 meters in many cases) without signal degradation, even in noisy industrial or automotive environments.

3. Core Components of an LVDS Cable

An LVDS Cable is more than just two twisted wires—it’s a engineered assembly with several components working together to optimize performance:

a. Differential Pair Conductors

The heart of the cable is the differential pair: two insulated copper wires twisted together at a precise pitch (twists per inch). Twisting ensures the wires are exposed to identical EMI and minimizes “crosstalk” (signal leakage between adjacent wires). The copper conductors are often tinned or plated to reduce oxidation and improve conductivity.

b. Shielding

Many LVDS Cables include a metallic shield (e.g., aluminum foil or braided copper) around the differential pair. This shield acts as a barrier against external EMI and prevents the LVDS signals from interfering with other nearby cables (a problem called “EMI emission”). Shielding is especially critical in industrial or automotive applications, where EMI levels are high.

c. Insulation and Jacket

Each conductor is coated with a thin layer of insulation (e.g., polyethylene or polyvinyl chloride, PVC) to prevent short circuits between the differential pair. The entire assembly is then covered in an outer jacket (often PVC or flame-retardant materials like FRPE) for mechanical protection against wear, moisture, and temperature extremes.

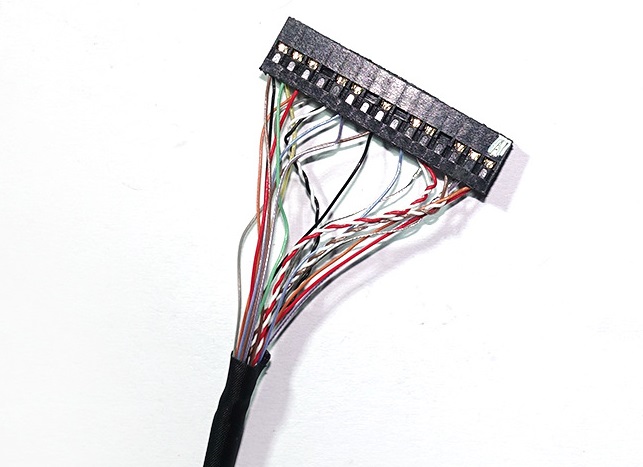

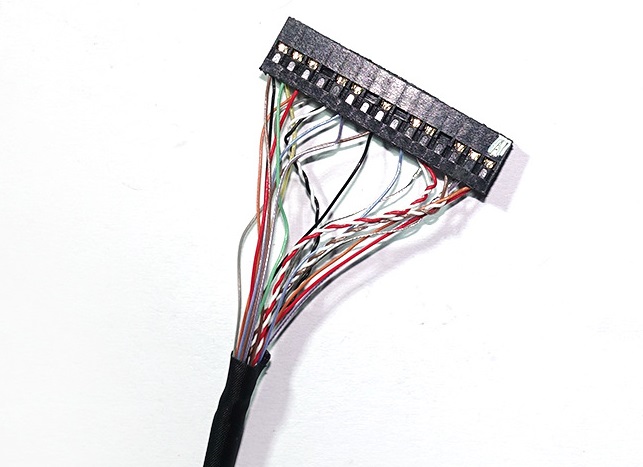

d. Connectors

LVDS Cables use specialized connectors designed to maintain the integrity of the differential signal. Common connector types include JAE MX19, Hirose DF19, and Samtec FTSH—all of which feature precise pin spacing to minimize signal skew (delays between the positive and negative signals) and ensure a secure, low-resistance connection.

4. Key Characteristics of LVDS Cables

LVDS Cables’ popularity stems from four defining traits that address critical industry needs:

a. High Bandwidth

LVDS supports data rates ranging from 100 Mbps to over 10 Gbps, making it ideal for applications that require fast, real-time data transfer. For example, a 4K LCD display needs a bandwidth of ~18 Gbps to transmit video signals—something LVDS Cables (often in multi-pair configurations) can handle reliably.

b. Low Power Consumption

Because LVDS operates at 350 mV (far lower than legacy standards), LVDS Cables require minimal power to transmit signals. This is a game-changer for battery-powered devices like laptops, tablets, and portable medical monitors, where energy efficiency directly impacts battery life.

c. Low EMI and Noise Immunity

As explained earlier, differential signaling cancels out EMI, while shielding further reduces interference. This makes LVDS Cables suitable for noise-prone environments like factories (with heavy machinery) or cars (with engine electronics and power systems).

d. Compact Design

LVDS Cables are thin and flexible, thanks to their small-gauge conductors and minimal insulation. This is critical for devices with limited space, such as smartphones, wearable tech, or industrial robots—where bulky cables would hinder performance or fit.

5. Real-World Applications of LVDS Cables

LVDS Cables are ubiquitous across industries, powering devices we use daily and critical industrial systems:

a. Consumer Electronics

-

Displays: Most laptops, LCD/LED televisions, and gaming monitors use LVDS Cables to connect their graphics cards to the screen panel. For example, a 15-inch laptop’s LCD panel relies on an LVDS Cable to transmit 1080p video signals without lag.

-

Smartphones/Tablets: While newer devices use MIPI D-PHY (a derivative of LVDS), many mid-range smartphones still use LVDS Cables for internal camera-to-processor data transfer.

b. Industrial Automation

-

Machine Vision: Industrial cameras (used for quality control in factories) use LVDS Cables to send high-resolution images to control systems in real time. For example, a car manufacturing plant might use an LVDS-equipped camera to inspect welds on a production line, with the cable ensuring no image data is lost.

-

Robotics: Industrial robots use LVDS Cables to transmit sensor data (e.g., position, torque) to their controllers, enabling precise, fast movements.

c. Medical Devices

-

Imaging Equipment: MRI, CT scanners, and ultrasound machines generate massive amounts of data. LVDS Cables transmit this data to displays and storage systems without distortion, ensuring doctors get accurate images for diagnosis.

-

Portable Monitors: Patient monitors (used to track heart rate and blood pressure) rely on LVDS Cables for low-power, noise-free data transfer—critical in hospital environments with multiple electronic devices.

d. Automotive

-

Infotainment Systems: Modern cars use LVDS Cables to connect their touchscreens to the infotainment unit, enabling smooth playback of navigation maps, music, and rearview camera feeds.

-

Driver Assistance: ADAS (Advanced Driver Assistance Systems) components like lane-keeping cameras use LVDS Cables to send real-time video to the car’s ECU (Engine Control Unit), helping prevent accidents.

6. LVDS Cables vs. Alternatives

While LVDS Cables are widely used, they face competition from newer standards like MIPI D-PHY (for mobile devices) and DisplayPort (for high-end displays). However, LVDS remains dominant in many areas because:

-

It is cost-effective compared to DisplayPort.

-

It is simpler to implement than MIPI D-PHY for non-mobile applications.

-

It offers better noise immunity than single-ended alternatives like TTL.

In short, an LVDS Cable is far more than a simple set of wires—it is a precision-engineered solution that enables the high-speed, reliable data transfer that powers modern technology. By leveraging differential signaling, low-voltage operation, and robust design, LVDS Cables address key challenges of EMI, power consumption, and space constraints, making them indispensable in consumer electronics, industrial automation, medical devices, and automotive systems. As demand for faster, more efficient data transfer grows—from 8K displays to autonomous vehicles—LVDS Cables will continue to play a vital role in shaping the future of connectivity.